The effects The water to quality metal cutting Fluids

Impurities in the water can react with cutting oil and a strong influence on the performance of processing. Over the course of the reaction or impurities associated with this impure cutting oil can be changed. Therefore, water treatment is necessary to get a cold coolant perfect irrigation.

WATER QUALITY

Water quality changes over water are provided. It may contain dissolved minerals, organic matter and air microorganisms. Use water from rivers or lakes near mineral resources will have a high mineral content and vice versa. Usually well water used in the process of metal cutting oil phase, it has many kinds of minerals should tend to transform cutting unwanted oil. The water contained in the tank containing higher amounts of microorganisms causing bacteria and mold easily damaged cutting oil therefore needs treatment before this phase cutting oils.

Some of the metal processing plant water use and type information for details on their composition. Most of the water supplied by municipal water works, water is analyzed every day and every tuan.luong mineral and water are bacteria in check is essential to quality metal cutting oil and water phase.

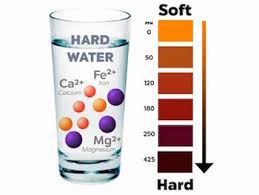

TOTAL hardness

Among the results of the analysis, the total water content hard to assess the quality of the clearest water. . Hardness comes from dissolved minerals and ions typically calcium magnesium ion was assessed by content (ppm) and calcium carbonate expressed as the equivalent (CaCO3).

Hardness of water ideal for metal cutting oil phase was delivered in about 80 ~ 125 ppm. Soft water is water with a total hardness less than 100 ppm concentration or "hard" if total hardness exceeds 200ppm.

Water Softening

When using soft water to oil phase can cut foam, especially in the processing method with high pressure. Foam is made up as it flows overflow reservoirs, equipment error. Foam reduces the contact surface (as it dangling and prevent sedimentation), blurring the embryo and reduces the cooling capacity of the oil and water phase trimming.

Cutting oil and water phase mineral semi-synthetic cutting oil, tend to have more foam than in soft water. After using oil Cutting oil for a few days exposure to metal dust and oil residues tend to reduce foam away. The foam must be controlled by checking the system, the physical conditions contribute to foam excessively abrupt change valve flow, high pressure nozzles, pump malfunction. If not, have to choose a cutting oils capable of breaking foam in hard water conditions and water mixed with soft.

Hard water

Hard water when combined with some quality in metal cutting oil mixed with water, making the oil more soluble. The water dissolved minerals in combination with anionic emulsifier in oil Cutting forming insoluble compounds cause sediment in the mixture. This covered residues located at the corner of the pool cooling pipes and clog the filter, cover and cause dirty machine after processing.

Because oil mixed with hard water Cutting least stable, clear hard water affects emulsion system. Causing separation layer in the solution is a serious problem, oil is on the water underneath the main reason for this is detailed equipment corrosion rust.

Semi-synthetic cutting oil and synthetic less affected by water hardness. Some are formed with solubility with water. However, the minerals will react with other components in the oil changed and oil components cutting.

Mineral content in the oil phase mixture increases in metalworking. After about 30 days, the content of the mixture can be increased to 3 ~ 5 times the original sample. This effect results "boiler" exists in a storage tank metalworking fluid. It is the water evaporates, leaving the dissolved minerals underneath. Then this component accumulated more (typically 3-10% per day). So with water dissolved minerals despite very low, they can build up and cause problems.

SELECTION OF WATER TREATMENT

content of soft and hard water is determined by analyzing nuoc.Tuy on-demand water quantity, water quality requirements and economic considerations in the selection of appropriate water treatment .

Soften hard water scum remover, liquid mixtures of metal, but increases the likelihood of corrosion problems.

We recommend using substances demineralized deionized or reverse osmosis. Ion reducing agent typically lower cost compared to reverse osmosis equipment, but higher operating costs.

Ion reducing agent can provide higher quality water, but the plastic film to be reborn

regularly. If not regenerated regularly, water quality will decline and plastic film will also create favorable conditions for the growth of bacteria. Reverse osmosis devices without regeneration, but the need to replace the membrane in a time depending on the quality of water supplied to the device. Pretreatment system, before being demineralized or reverse osmosis membranes generally prolong the life of equipment.

With demineralized method, the foam can be a problem when the load on the system. To avoid bubbles, the initial cost can be made with untreated water (except where dissolved mineral content were excessive) and the next step may be mixed with demineralized water. Shavings, granulates and final piece of metal will create impurities in the water the first time, but the number is negligible when compared to not using the water already treated. Many of our customers handle poor quality water before it enters the oil blend mixed metal cutting.

For example a customer has used cutting oil mixed with water in our report that the demineralized water has eliminated some of the problems seem to occur with any metal cutting oil that he uses. Which he uses water taken from the city there is a large change in the mineral composition dissolved because of frequent changes in the water treatment process. After this water through a demineralization equipment, he took water with appropriate hardness.

Cost savings will demineralised by the use of cutting oil mixed with water. Saving the replacement filter maintenance. Demineralized water also reduces the use of additives and the proportion corresponding skin irritation.

This customer has concluded that the benefits of using demineralized water are worth the investment. Also he has a consistent water quality, eliminates a large amount when searching for the source of any performance problems reduce any metal cutting oil.

main.comment_read_more